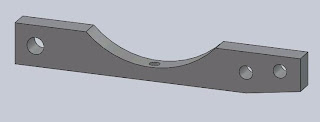

I came up with this basic design a few days ago, but dismissed it because two 3/8" brackets will be fine to resist motor torque and vertical/hoizontal loading from the chain tension. But loads parallel to the shaft need something else. It came to me this morning, add an angle bracket and use the mounting holes in the case. (edit one year later: no additional pieces needed, the dual bracket arrangement is plenty strong with regards to axial loads.)

I was so jazzed at having a solution, I cranked out the template to make the wood prototype. I also tweaked the geometry on the left bracket, thinking I could cut them both and have the wood parts done. Haste makes waste...

I neglected to check if I had enough RotoZip bits

and busted my last one starting the new bracket. I did manage to cut out a sloppy version of the left bracket, so at least I could get it fitted. Wrong-O! In adjusting the bolt pattern location, I appearantly changed the bolt circle diameter, making that version completely worthless. The only bright side of these wasted efforts is that it's only wood, not the actual 3/8" Aluminum.